Manufacturing

Manufacturing Facilities

KRC Chemicals is one of the leading pharmaceutical manufacturing companies in India with efficient and class facilities, with a wide range of process equipment fully compliant with the national and international standards.

KRC has over the years developed tremendous manufacturing facilities to suit its style of operations and to meet the requirements of our global clientele. We have capabilities in wide range pharmaceutical intermediates and have handled varied process reactions and large reactor volumes.

Our commitment to quality and productivity is reflected in the implementation of total quality management processes at every stage of the manufacturing life cycle which is acknowledged by our ever-expanding list of clienteles globally.

Contract Manufacturing

KRC can undertake multiple chemical reactions in the plant with expert technical supervision. With these facilities we are looking for long term business relations with well known and stable players in APIs & Advanced intermediates.

Plant Equipment

| Sr. No. | Equipment | Capacity | MOC | Remark |

|---|---|---|---|---|

| 1 | SS Reactor with Condenser & Receiver | 5 KL | SS-316 | Anchor |

| 2 | SS Reactor with Condenser & Receiver | 5 KL | SS-316 | Anchor |

| 3 | SS Reactor with Condenser & Receiver | 5 KL | - | - |

| 4 | SS Reactor with Condenser & Receiver | 3 KL | SS-316 | Anchor |

| 5 | SS Reactor with Condenser & Receiver | 3 KL | SS-316 | Anchor |

| 6 | SS Reactor with Condenser & Receiver | 2 KL | - | - |

| 7 | SS Reactor with Condenser & Receiver | 1.5 KL | SS-316 | Anchor |

| 8 | SS Reactor with Condenser & Receiver | 1 KL | SS-316 | Anchor |

| 9 | Glass Line Reactor with Glass Assembly | 5 KL | MSGL | Propeller |

| 10 | Glass Line Reactor with Glass Assembly | 3 KL | MSGL | Propeller |

| 11 | Glass Line Reactor with Condenser & Receiver | 3 KL | - | - |

| 12 | SS Centrifuge | 36" | SS-316 | - |

| 13 | SS Try Dryer | 48 Try | SS-316 | - |

| 14 | Multi Mill | - | SS-316 | - |

| 15 | Agitated Nutsche Filter Dryer (ANFD) | 3 KL | - | - |

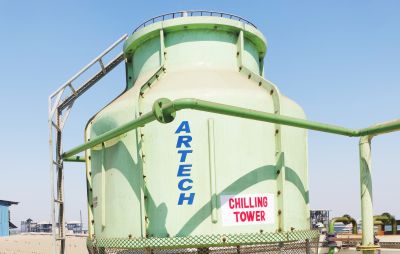

Utility Equipment

| Sr. No. | Equipment | Capacity | MOC | Remark |

|---|---|---|---|---|

| 1 | Steam Boiler | 1 Ton. | Energy Pack | Gas |

| 2 | Cooling Tower | 200 TR | - | 1 Set |

| 3 | Water Ejector | - | PP | 3 No. |

| 4 | Steam Ejector | - | Teflon | 1 No. |

| 5 | High Vacuum Pump | 150 CFL | HK | 1 No. |

| 6 | High Vacuum Pump | 250 CFL | HK | 1 No. |

| 7 | DG Set | 125 KV | Kirloskar | 1 Set |

| 8 | Thermic Oil Boiler | 1 Lac/cal. | Patel Boiler | 2 Set |

| 9 | Chilling Plant | 40 TR | Voltas | - |

| 10 | SS Storage Tank | 13 KL | - | 1 No. |

| 11 | HDPE Storage Tank | 13 KL | - | 2 No. |